MACHINING OF MEDICAL DEVICES

Turning precision parts in series

DESIGN

DEVELOPMENT

MANUFACTURING

COMMERCIALIZATION

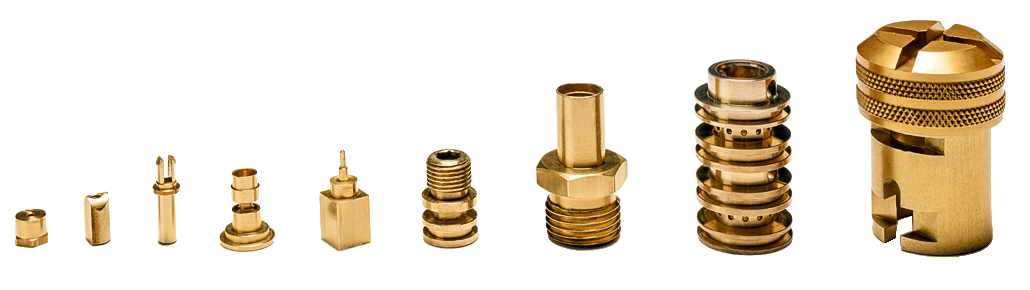

Our company has the latest technology to control and maintain maximum quality in all its processes. We offer products that save time and money and we machine for any industrial sector that requires machining quality parts.

I+D

We are specialists in developing projects for Medical Devices

PRODUCTION

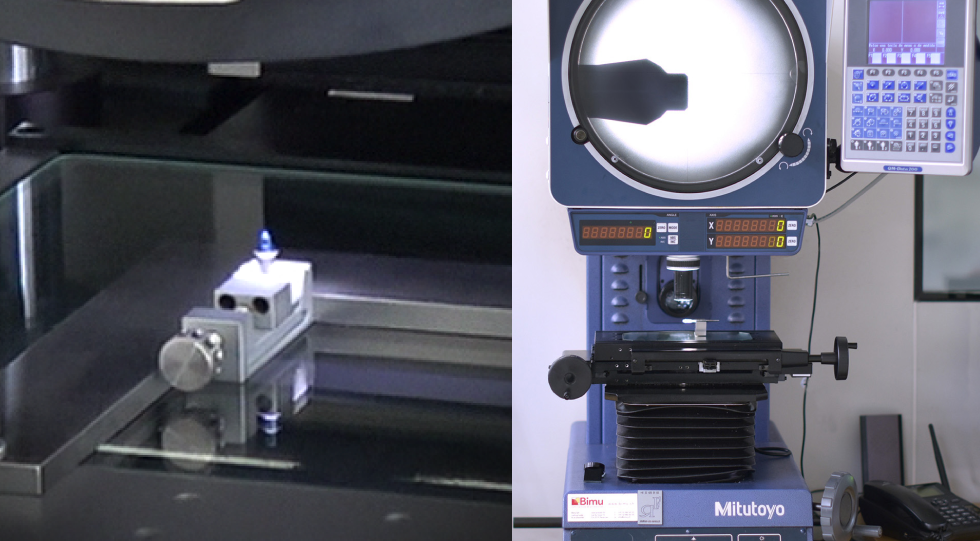

High precision machinery that guarantees the best finishes in any geometry

CERTIFICATION

We advise you on the approval process for Medical Devices

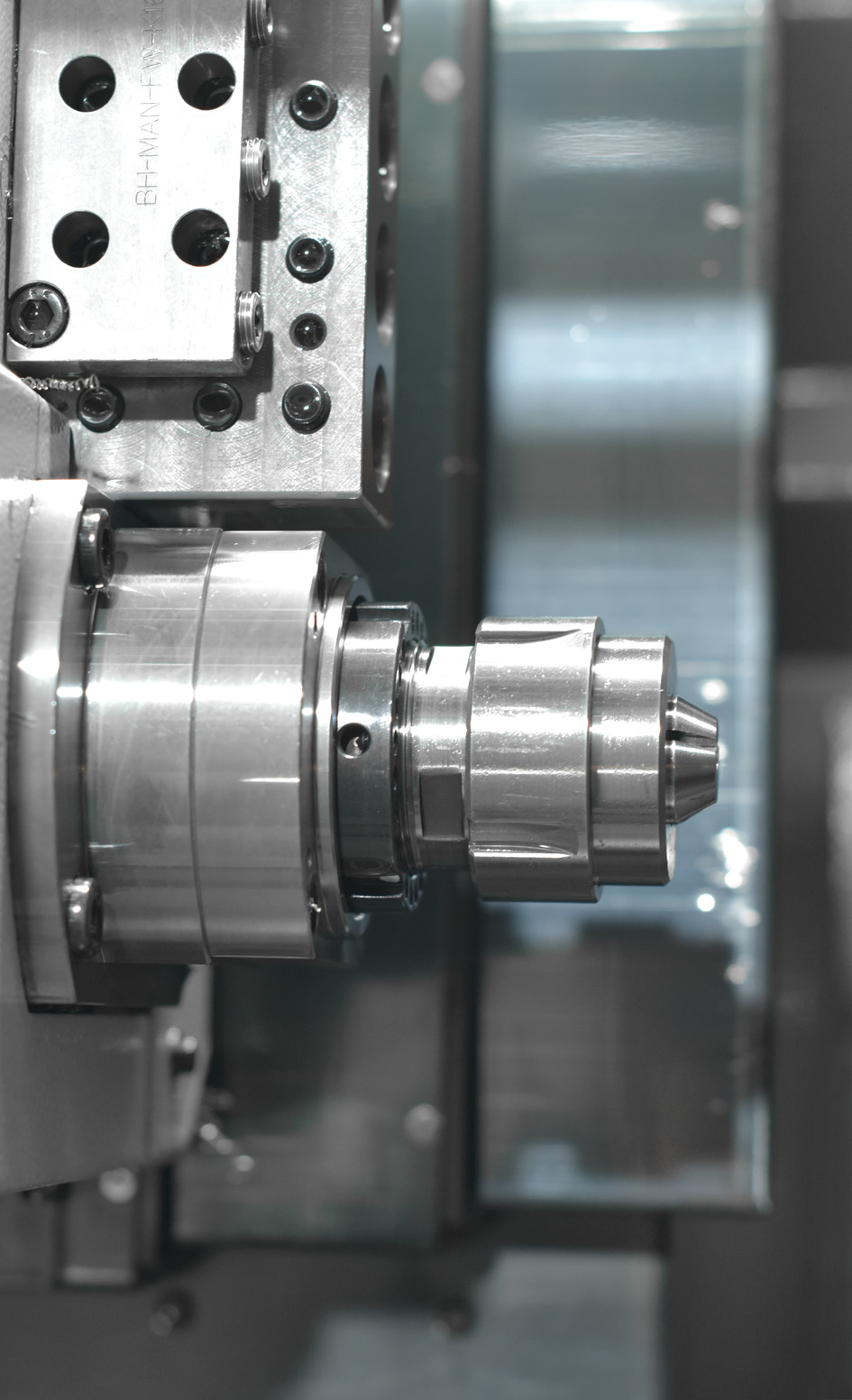

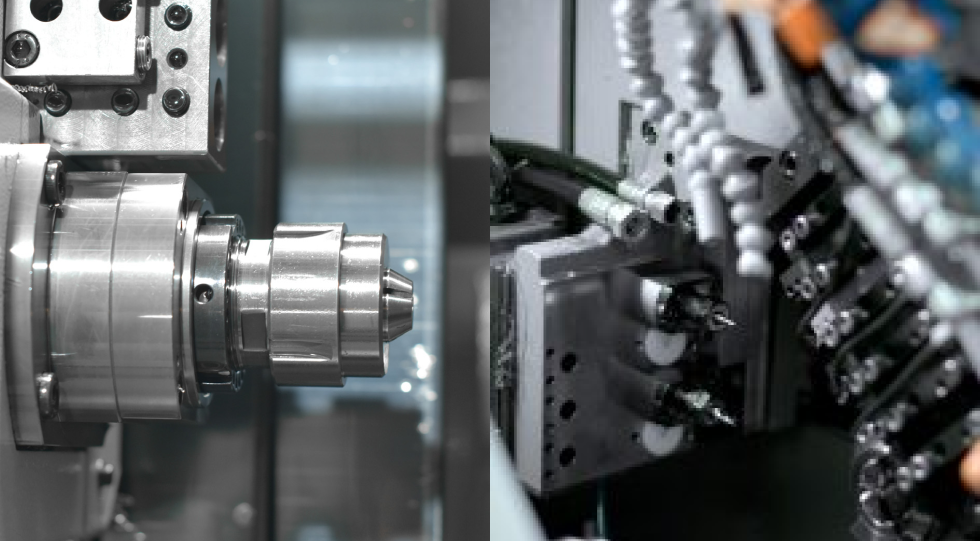

CNC MACHINING

We work with CNC numerical control lathes for the production of high added value parts in any type of material, from Ø1mm to Ø26mm. It allows us to handle the manufacturing of prototypes and at the same time be competitive in large series.

We constantly invest in top brand machinery:

SectORs

More than 50 years of experience and constant development with projects for many sectors.

Motoring

Electronics

Hydraulics

Medical

Dental

Aeronautics

Electricity

Pneumatics

Instrumentation

This is the secret of the high quality of our products…

Starting from the best raw materials, we manufacture our products using capable and stable processes, considering personal integrity, creativity and innovation as essential parts of our daily challenge to continuous improvement.

QUALITY

The secret to the high quality of our products is to use the best raw materials and manufacture with efficient and stable processes.

EM EXACT, S.A. It has a quality system that guarantees product quality in all phases from manufacturing through cleaning/decontamination to visual inspection and packaging.

All products comply with Directive 93/42/EEC as amended by Directive 2007/47/EEC.

Our management system is certified according to ISO 13485 for the development, manufacturing and marketing of dental prostheses and their accessories.

Clean Room

We have a Clean Room Class 100,000 of the Federal Standard 209D and ISO Class 8 of the ISO 14644-1 Standard.

Inside the White Room:

· We verify all parts: All products, in addition to the inspection during the production phases, are 100% inspected at the end of the series.

· We package and seal with the help of the robot to guarantee a perfect and hygienic unitary seal.

HEALTH PRODUCT

LICENSE

emexact® committed to the precision of its components.

We have a license to manufacture health products issued by the AEMPS, Spanish Agency for Medicines and Health Products.

HISTORy

1963

ELECTROMECANICA EM was founded to satisfy the needs of companies that need the close collaboration of a supplier that offers quality, seriousness, precision and flexibility.

1983

The first numerical control lathe is acquired, which marks the evolution of the investment since currently this type of machinery accounts for 100% of the total.

1990

The company is transformed into a Public Limited Company with the name EM DECOLLETAGE, S.A.

1999

The Quality System certification is achieved according to the DIN EN ISO 9002: 1994 standard, accredited by the TÜV Rheinland firm.

2002

The certification is updated according to the new DIN EN ISO 9001: 2000 standard.

2011

The quality certificate is obtained according to ISO 13485:2003 Standard for Medical Devices and updated to the new ISO 9001:2008 Standard.

2012

The Medical Device Manufacturer License is obtained, granted by the AEMPS. Obtaining the CE Marking and entering the Health Products Market under the emexact® registered trademark.

2013

The company changes its corporate name to Em Exact, S.A., updating strategies, organizational chart and processes to further adapt to current requirements.

2014

Obtaining Certificates for Export of Health Products.

2023

We obtain the CE Marking certificate with the new European Union Health Products Regulation (MDR).

Our own brand of dental abutments

TURNING & MACHINING

At EM-DECOLLETAGE® we are dedicated to machining precision parts in series (turn turning). We manufacture our items for any industrial sector that requires quality parts.

What is part machining?

Machining is based on the transformation of the original raw material (metals, plastics, wood, etc.). The objective is to form specific parts through processes such as material removal, abrasion, electro-erosion or other forming methods without material removal, such as bending, lamination, forging, drawing, sintering, etc.

What is

bar turning?

Turning is a field of manufacturing in which revolution parts are machined by removing material from bars using a cutting tool. Thus, the parts are machined in small, medium or large series on conventional automatic lathes or with numerical control. They are machined one after another on the bar, with the aim of achieving high productivity and precision, seeking to produce the smallest number of chips possible.